Introduction to MP2459GJ-Z and Its Role in High-Efficiency Step-Down Power Supplies

In today's rapidly evolving electronics landscape, the demand for energy-efficient, compact, and reliable power solutions has never been greater. High-efficiency power supplies are a key part of this trend, providing stable and reliable power to a wide range of devices while minimizing energy losses and heat generation. One such solution that stands out in the realm of step-down (buck) converters is the MP2459GJ-Z.

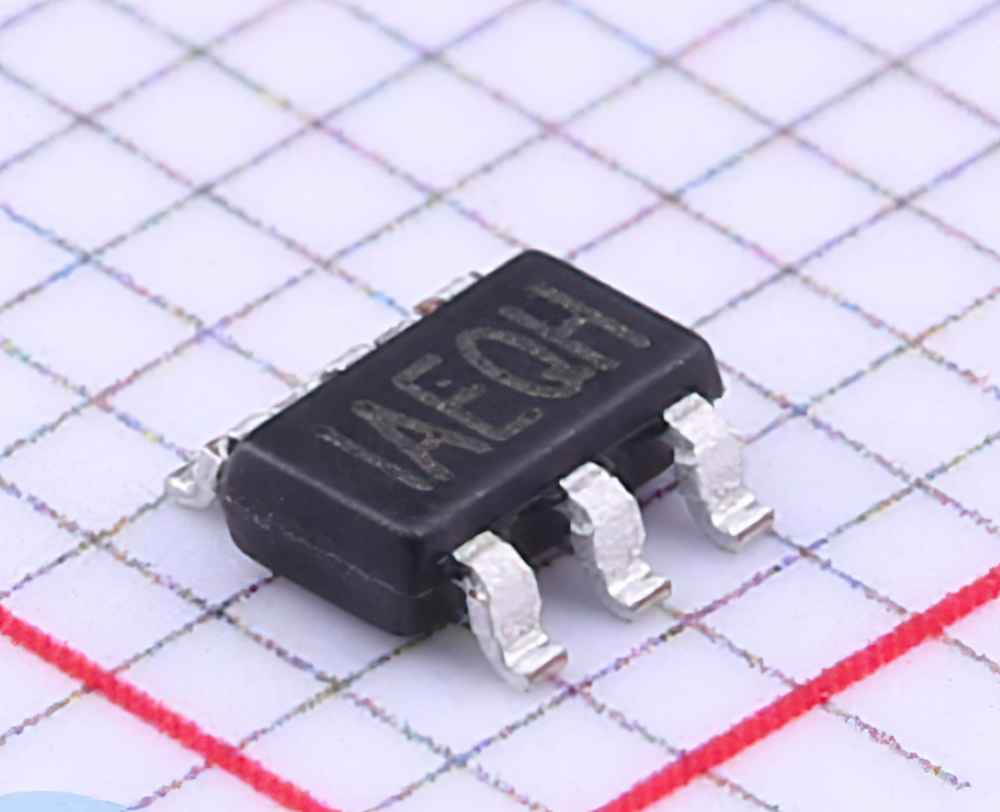

The MP2459GJ-Z is a high-performance DC-DC buck converter manufactured by Monolithic Power Systems (MPS). It is specifically designed to deliver high efficiency, compact size, and excellent Thermal Management , making it an ideal choice for applications in power supplies where efficiency and heat Management are critical. This article delves into the applications of the MP2459GJ-Z in high-efficiency step-down power supplies, as well as the crucial role that thermal design plays in maximizing its performance.

What is the MP2459GJ-Z?

The MP2459GJ-Z is a synchronous step-down regulator, capable of efficiently converting higher input voltages (up to 60V) to lower, more stable output voltages. It operates in a wide range of applications, from powering microcontrollers and processors to providing power for Communication equipment, industrial control systems, and automotive applications. The MP2459GJ-Z integrates advanced features that enable high efficiency, such as:

Low Quiescent Current: Ensures minimal standby power consumption, ideal for battery-powered devices.

Wide Input Voltage Range: Accommodates various source voltages, making it versatile for different applications.

Internal Synchronous Rectification: Improves efficiency by reducing conduction losses.

Power-On Reset (POR): A feature that ensures the converter operates reliably upon startup.

At its core, the MP2459GJ-Z ensures power is delivered in a way that minimizes losses, heat generation, and overall system footprint, making it ideal for high-efficiency step-down power supplies.

Applications of the MP2459GJ-Z

The versatility of the MP2459GJ-Z allows it to be used in a variety of applications, making it a go-to solution for engineers seeking to improve efficiency in power supply designs. Here are some of the key applications:

Consumer Electronics:

Many modern electronic devices, such as smartphones, laptops, and wearables, demand efficient power supplies to maintain optimal performance without draining the battery. The MP2459GJ-Z is well-suited for converting high-voltage inputs from power adapters to lower, stable output voltages for charging circuits, processors, and other critical components.

Automotive Power Systems:

Automotive applications, particularly those involving infotainment systems, sensors, and electric control units (ECUs), benefit from the MP2459GJ-Z’s ability to convert high input voltages from the car battery to the required operating voltages for various subsystems. Given the harsh environments in vehicles, thermal management is critical, and the MP2459GJ-Z excels in maintaining thermal performance even in high-stress conditions.

Industrial Automation:

Powering industrial controllers, sensors, actuators, and other machinery often requires efficient DC-DC conversion. The MP2459GJ-Z’s wide input voltage range and high efficiency make it ideal for powering these devices in factory automation, robotics, and instrumentation, where heat dissipation and energy consumption are key considerations.

Telecom munications Equipment:

Communication devices, including routers, base stations, and repeaters, rely on reliable, efficient power supplies to ensure continuous operation. The MP2459GJ-Z is frequently used in these systems to provide the necessary power conversion for various module s within the equipment, ensuring long-lasting and reliable service.

Medical Devices:

Many medical devices require precision power supplies to ensure proper functioning and reliability. From portable patient monitors to medical imaging equipment, the MP2459GJ-Z plays a crucial role in providing efficient power conversion without excessive heat generation, which could compromise the device's operation.

Why High Efficiency Matters

In the realm of power supply design, efficiency is paramount. A high-efficiency step-down power supply ensures that more of the input energy is converted into usable output power, rather than being lost as heat. The benefits of high-efficiency power conversion include:

Reduced Heat Generation: Less energy lost as heat means the power supply stays cooler, reducing the need for large heatsinks or active cooling mechanisms.

Lower Power Consumption: Increased efficiency translates to lower overall power consumption, which is especially important in battery-powered applications where battery life is crucial.

Improved Reliability: Excess heat can degrade electronic components over time, reducing the overall lifespan of the system. By minimizing heat generation, high-efficiency power supplies increase system reliability.

Smaller Form Factor: With less heat generation, the power supply design can be more compact, allowing for smaller devices or a reduction in the physical space needed for cooling.

The MP2459GJ-Z is engineered to provide the high efficiency necessary for modern electronics, allowing engineers to meet these demands and deliver optimal performance.

Challenges in Thermal Design

While high efficiency is a core feature of the MP2459GJ-Z, achieving that efficiency while managing heat dissipation remains a challenge. In step-down converters like the MP2459GJ-Z, heat is primarily generated by power losses during the conversion process. These losses are inevitable but can be minimized through careful thermal design.

Several factors contribute to the thermal performance of a power supply:

Power Losses in the Switches : The internal MOSFETs (metal-oxide-semiconductor field-effect transistor s) that switch the current on and off during the step-down conversion process generate heat due to switching and conduction losses.

Inductor and capacitor Losses: The passive components involved in the conversion, such as Inductors and Capacitors , also introduce losses that contribute to the overall thermal load.

Package and PCB Layout: The thermal Resistance of the converter’s package and the layout of the PCB can have a significant impact on the heat dissipation. A poor PCB layout can trap heat, preventing it from dissipating efficiently.

By understanding these factors and employing strategies like optimizing the layout, using high-quality passive components, and selecting appropriate heat sinks or cooling solutions, engineers can effectively manage the thermal performance of the MP2459GJ-Z.

Thermal Management Techniques for the MP2459GJ-Z in High-Efficiency Power Supply Designs

Effective thermal management is essential for ensuring the reliability and efficiency of power supply systems. In this section, we will explore some of the key thermal design techniques that can be used with the MP2459GJ-Z to maintain its performance in high-efficiency step-down power supplies.

Thermal Performance Characteristics of the MP2459GJ-Z

To better understand the thermal management needs, it is important to first examine the thermal characteristics of the MP2459GJ-Z. When designing a power supply that incorporates this converter, engineers need to take into account:

Power Dissipation: The MP2459GJ-Z features low Rds(on) MOSFETs, which reduces conduction losses. However, some power dissipation will still occur due to the internal switching transitions and losses in the passive components.

Thermal Resistance of the Package: The device's package, including its thermal resistance, plays a crucial role in determining how efficiently heat can be conducted away from the chip. MPS has designed the MP2459GJ-Z package with low thermal resistance to aid heat dissipation.

Operating Ambient Temperature: The ambient temperature surrounding the power supply affects the ability of the MP2459GJ-Z to dissipate heat. Higher ambient temperatures require more effective cooling solutions to maintain the temperature within safe limits.

Thermal Management Techniques

Several methods can be employed to effectively manage the heat generated by the MP2459GJ-Z:

PCB Design and Layout Optimization:

The layout of the printed circuit board (PCB) is one of the most important aspects of thermal management. A well-designed PCB ensures optimal heat dissipation by providing ample copper area for heat spreading and routing current paths efficiently to reduce losses.

Key considerations for PCB layout include:

Thermal vias: Strategically placing thermal vias under the device can help transfer heat from the package to the backside of the PCB, where it can be dissipated into the surrounding environment.

Copper Area: Increasing the copper area near the converter and routing power traces efficiently helps spread heat more evenly across the PCB.

Ground Plane: A continuous, low-resistance ground plane enhances thermal conductivity, helping to dissipate heat more effectively.

Use of External Heat Sinks:

In cases where the power dissipation is higher or the thermal environment is more challenging, external heatsinks can be used to further enhance heat dissipation. A properly sized heatsink can significantly reduce the temperature rise of the MP2459GJ-Z, ensuring that the converter remains within its safe operating temperature range.

Use of Low ESR Capacitors and High-Quality Inductors:

The quality of the passive components used in the power supply also plays a role in thermal management. Low ESR (Equivalent Series Resistance) capacitors and high-quality inductors reduce internal losses, resulting in less heat generation.

Active Cooling Solutions:

In some high-power applications, where the thermal load is particularly high, active cooling solutions such as fans or thermoelectric coolers can be used to maintain acceptable temperatures. These solutions may add complexity and cost to the system but can be necessary for demanding applications.

Ambient Temperature Control:

Ensuring the power supply operates in a controlled environment with consistent ambient temperatures is crucial. Higher temperatures require better heat dissipation strategies, so designing systems that can function within a specified temperature range can help maintain efficiency and reliability.

Conclusion

The MP2459GJ-Z is an excellent choice for high-efficiency step-down power supply designs, offering a combination of versatile applications, robust performance, and energy savings. However, achieving optimal performance requires a careful balance between efficiency and thermal management. By leveraging best practices in PCB design, component selection, and thermal optimization, engineers can ensure that the MP2459GJ-Z operates reliably and efficiently in a wide range of applications, from consumer electronics to industrial systems and automotive applications.

Incorporating these techniques into your power supply design will help maximize the MP2459GJ-Z's efficiency, reliability, and longevity, ensuring that your products perform at their best while keeping thermal performance under control.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.