This article delves into common troubleshooting techniques and solutions for the OPA365AIDBVR operational amplifier, guiding users to resolve issues efficiently and optimize the pe RF ormance of this versatile component in various applications.

Understanding the OPA365AIDBVR and Common Issues

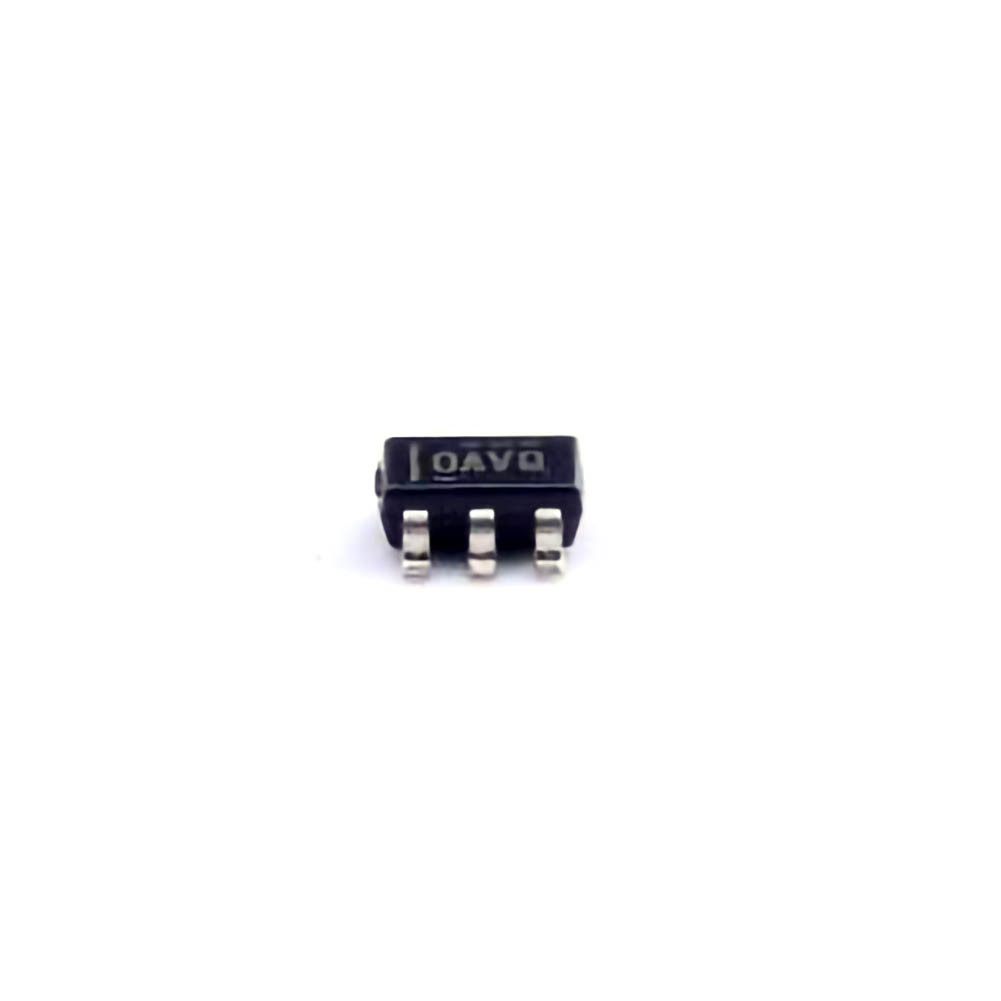

The OPA365AIDBVR is a high-precision, low- Power operational amplifier designed for a wide range of applications, from signal conditioning to audio amplification and Sensor interfacing. Its features, such as low noise, low input bias current, and rail-to-rail output swing, make it a versatile component in many electronic circuits. However, like any electronic component, it is susceptible to a variety of issues that can compromise its performance. Understanding common troubleshooting scenarios can help users address these issues quickly and efficiently.

1.1. Overheating and Power Supply Issues

One of the most frequent issues encountered with the OPA365AIDBVR, and operational amplifiers in general, is overheating. This can result in the amplifier failing to operate correctly or even permanent damage to the component. The OPA365AIDBVR is designed to operate within a specified range of supply voltages (from 1.8V to 5.5V), and exceeding these limits can cause the part to overheat.

Solution:

Ensure that the power supply voltage is within the recommended range. A regulated power supply should be used, and any fluctuations or noise in the supply voltage should be minimized. Use appropriate heat dissipation techniques, such as heat sinks or thermal vias on the PCB, to manage temperature in high-power applications.

1.2. Excessive Noise in the Output Signal

Another issue that engineers commonly face with operational amplifiers, including the OPA365AIDBVR, is noise. Excessive noise in the output signal can compromise the integrity of the entire circuit, especially in audio and sensor applications where clarity and precision are essential.

Solution:

Noise can be minimized by placing proper decoupling capacitor s near the power supply pins of the OPA365AIDBVR. A common practice is to use a 0.1µF ceramic capacitor in parallel with a 10µF electrolytic capacitor. Additionally, ensure that the PCB layout is optimized to reduce noise interference. Proper grounding, shielding, and the use of low-noise components can also significantly reduce unwanted noise.

1.3. Output Saturation or Clipping

Another common problem with operational amplifiers is output saturation or clipping. This occurs when the output voltage of the amplifier reaches its maximum or minimum allowable value and cannot swing any further, even if the input signal continues to increase. This is particularly problematic when precision is key, such as in high-accuracy sensors or audio amplification.

Solution:

Output clipping typically occurs when the input signal exceeds the input range of the operational amplifier or when the supply voltage is insufficient. To avoid saturation, ensure that the input signal is within the recommended voltage range and that the supply voltage is adequate to allow for the full output swing. If necessary, reduce the input signal amplitude to prevent clipping.

1.4. Input Bias Current and Offset Voltage Issues

The OPA365AIDBVR, like all operational amplifiers, has a small but non-zero input bias current. This current can lead to unwanted voltage drops across external resistors, causing an offset at the output. This issue is especially critical in precision applications like sensor interfacing or instrumentation, where even small offsets can lead to significant errors.

Solution:

To mitigate input bias current effects, use resistors with low tolerance values, and if possible, compensate for any offset voltage using external trimming circuits. The OPA365AIDBVR has a low input bias current, but in sensitive applications, careful circuit design is essential to minimize these errors.

1.5. Instability and Oscillations

Another troublesome issue that users may face with the OPA365AIDBVR is instability and oscillations. This typically occurs in high-gain or high-frequency applications, where the amplifier may start to oscillate or behave unpredictably.

Solution:

Oscillations can be mitigated by properly selecting feedback and compensation components. A series resistor in the feedback loop can help to stabilize the amplifier and prevent oscillations. If using the OPA365AIDBVR in a high-frequency application, ensure that the PCB layout minimizes parasitic inductance and capacitance, which could trigger instability. Also, consider adding compensation capacitors to control the frequency response and prevent oscillations.

Advanced Solutions and Best Practices for OPA365AIDBVR Performance

Now that we’ve covered some of the common issues and basic solutions for the OPA365AIDBVR, let’s dive deeper into advanced troubleshooting techniques and best practices that can enhance the performance of the device in more complex applications.

2.1. Improving Linear Performance in Low-Voltage Applications

The OPA365AIDBVR is optimized for low-voltage operation, but users may encounter challenges when trying to maintain linear performance at voltages close to the lower end of the recommended operating range (1.8V). This can result in non-linear behavior, such as distortion or reduced output swing.

Solution:

To maintain linearity in low-voltage applications, use a higher supply voltage within the specified range. In many cases, increasing the supply voltage to around 3V or 5V can help ensure that the OPA365AIDBVR operates within its optimal performance range. Additionally, careful selection of external components, such as resistors and capacitors, can help maintain stability and linearity in low-voltage circuits.

2.2. Managing Input Impedance for Sensor Interfacing

When using the OPA365AIDBVR in sensor interfacing circuits, managing input impedance is crucial to prevent signal degradation or loss of accuracy. The input impedance of the OPA365AIDBVR is high, but the sensor’s output impedance may interact with it, leading to incorrect readings or reduced signal fidelity.

Solution:

To address this issue, it’s important to match the impedance of the sensor with the input impedance of the operational amplifier. Use a buffer stage, such as a follower configuration, between the sensor and the OPA365AIDBVR to avoid signal loading. Additionally, consider using lower impedance resistors or implementing active filtering techniques to ensure the integrity of the signal.

2.3. High-Frequency Performance and Parasitic Effects

At high frequencies, the OPA365AIDBVR may suffer from parasitic effects that can degrade its performance, such as signal distortion, phase shift, or increased noise. This is especially true in RF or high-speed data acquisition circuits.

Solution:

To optimize the performance of the OPA365AIDBVR at high frequencies, it is crucial to optimize the PCB layout. Minimize trace lengths to reduce parasitic inductance and capacitance, and use proper grounding techniques to shield sensitive signals. Using low parasitic components and paying close attention to the layout can significantly improve high-frequency performance. Additionally, consider placing a small-value capacitor (e.g., 10pF) in parallel with the feedback resistor to help with high-frequency stability.

2.4. Achieving Low Total Harmonic Distortion (THD)

In applications such as audio amplification, achieving low total harmonic distortion (THD) is essential for preserving the quality of the signal. While the OPA365AIDBVR is designed for low distortion, improper circuit design can introduce harmonic distortion, especially when driving loads or dealing with high gain.

Solution:

To reduce THD, ensure that the amplifier is operating within its linear region and avoid driving the amplifier into saturation or clipping. Using a higher-quality power supply with low ripple and noise will also help to reduce THD. Additionally, using external feedback loops and low-noise passive components can improve the linearity and reduce distortion in audio applications.

2.5. Using the OPA365AIDBVR in Low-Power Applications

The OPA365AIDBVR is a low-power operational amplifier, but achieving optimal power efficiency in battery-powered applications requires careful design. Excessive power consumption can shorten battery life and lead to inefficient operation.

Solution:

To optimize the OPA365AIDBVR for low-power applications, minimize the supply voltage while staying within the recommended range. Employ power-saving techniques such as turning off unused sections of the circuit or utilizing low-power modes when the device is idle. Additionally, consider using external low-power components and implementing sleep modes in the overall system to extend battery life.

Conclusion

The OPA365AIDBVR operational amplifier is a highly versatile component that excels in a wide variety of applications. By understanding the common issues and implementing the solutions and best practices outlined in this article, users can optimize the performance of this amplifier and ensure long-term reliability. Whether you are troubleshooting power supply issues, reducing noise, or improving high-frequency performance, the key to success lies in careful design, proper component selection, and attentive circuit layout. With these strategies in place, the OPA365AIDBVR can deliver the performance needed for even the most demanding electronic applications.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.